When people choose a white noise machine, they often focus on features like design or sound selection. But the most critical element—sound quality—is often overlooked. Clear, consistent sound without harsh tones or distortion is what defines a good white noise experience. Behind this sound lies an intricate process of audio engineering, designed to deliver therapeutic, non-intrusive background sound. So how exactly is sound quality developed and refined in white noise devices?

What Defines High-Quality Sound in White Noise Machines?

In a white noise machine, high sound quality means that the output is smooth, well-balanced, and free from peaks that irritate the ear. Poorly engineered devices might produce sound that’s too sharp, too bass-heavy, or distorted at higher volumes. For a white noise machine to be truly effective, especially for sleep or focus, the sound must be neutral, consistent, and pleasant over long listening periods.

This sound quality is determined by three main factors: the speaker unit, the digital signal processor (DSP), and the sound file or algorithm itself. The speaker must reproduce a broad frequency range cleanly. The DSP needs to shape and filter the audio signal accurately. And the sound content—whether recorded or digitally generated—must be curated to deliver a calming experience.

How Are Sound Profiles Designed and Calibrated?

The first step in engineering sound quality is the design of the sound profile. Audio engineers either record natural sounds (like rain, waves, or wind) or create synthetic white, pink, or brown noise using mathematical algorithms. Each type has a different emphasis across the frequency range—white noise treats all frequencies equally, pink noise reduces intensity with higher frequency, and brown noise emphasizes lower tones.

Once created, the sounds are tested in acoustic labs to remove sharp frequency spikes and ensure a soft, continuous texture. Engineers use spectrum analyzers to view the balance of frequencies and make adjustments accordingly. They also listen across different environments and speakers to refine the output.

Next, the final sound is embedded in the machine’s chip, often in high-resolution digital format. The DSP applies equalization (EQ), compression, and sometimes reverb to make the sound smoother. These tweaks ensure the output remains consistent across all volume levels.

How Do Speakers Affect Sound Output?

Even the best-designed sound profile can be ruined by a low-quality speaker. The speaker inside a white noise device must deliver sound evenly across a wide frequency range without buzzing or distorting. A well-matched speaker typically features a lightweight diaphragm and a tuned enclosure to minimize resonance and maximize clarity.

Engineers choose speaker sizes based on the desired audio output. For bedside sleep machines, smaller speakers with wide dispersion are ideal. For larger ambient devices, a slightly bigger driver might be used for fuller sound. The enclosure is also designed with acoustic engineering in mind—shape, materials, and internal damping all affect how clean the output sounds.

To ensure quality, speakers are tested under various conditions: full-range audio sweeps, burst tests at different volumes, and real-life room simulations. Only drivers that pass consistency tests are approved for mass production.

What Role Does the DSP Play in Sound Quality?

The Digital Signal Processor (DSP) is the brain behind the sound output. It processes the raw audio file, applying filters and shaping the waveform before sending it to the speaker. The DSP can eliminate harsh edges, boost desirable frequencies, and maintain clarity even at low or high volumes.

In premium white noise devices, the DSP can also support smart features like adaptive sound—where the volume adjusts based on room noise levels. Another common feature is frequency shaping based on time of day or sleep stages, adjusting tones to suit the user’s relaxation depth.

| DSP Feature | Function |

|---|---|

| Equalization (EQ) | Balances frequency ranges to remove harsh peaks or low muddiness. |

| Compression | Maintains consistent loudness without distortion. |

| Reverb/Spatial Effects | Adds natural echo or depth to recorded ambient sounds. |

| Noise Shaping/Generation | Creates white, pink, or brown noise mathematically. |

How Is Sound Tested Before Mass Production?

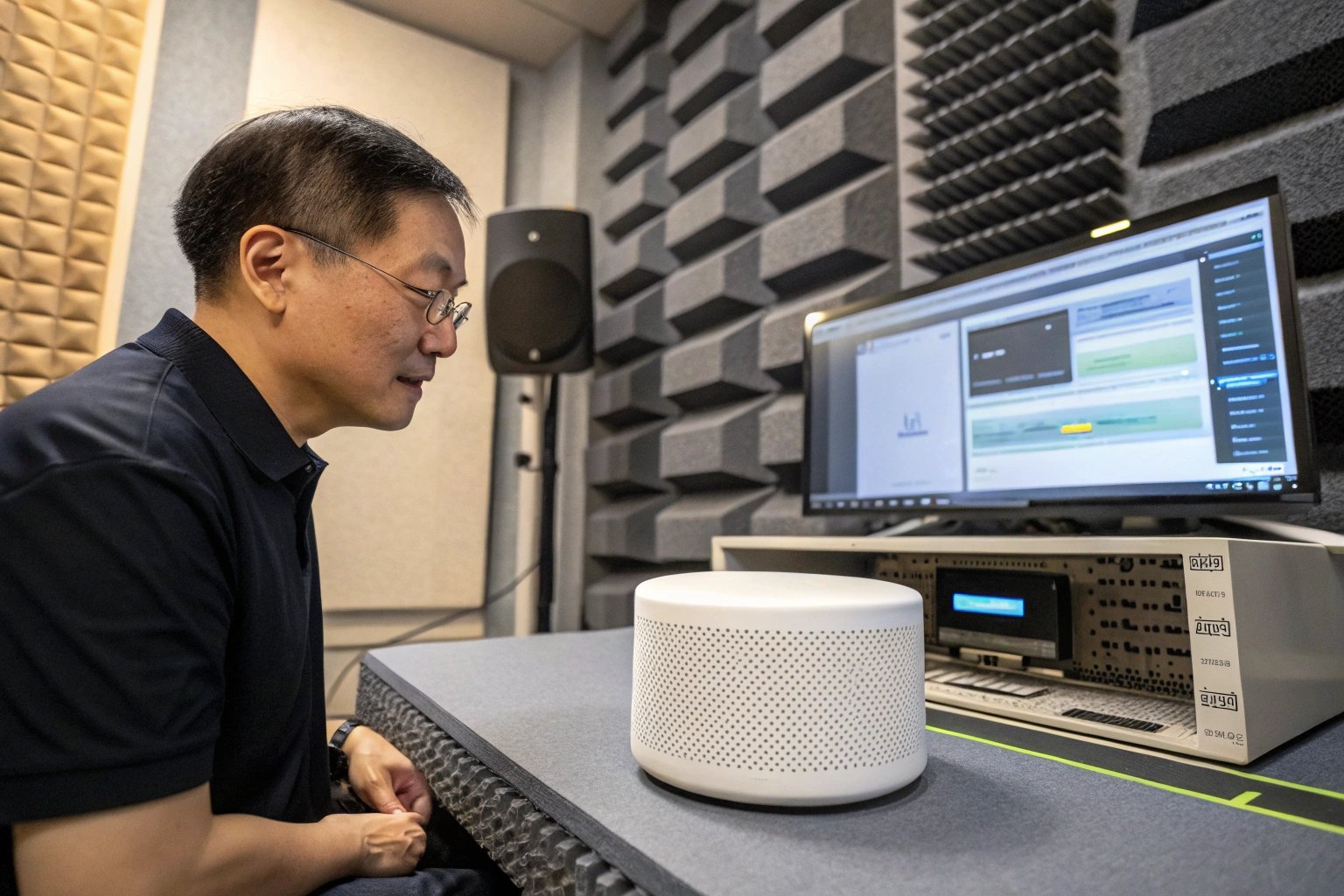

Before any white noise device goes into full production, extensive testing is performed to ensure sound quality remains consistent. First, units are tested in anechoic chambers—special rooms that eliminate echo and background noise—to measure how the sound behaves in a controlled environment.

Each prototype is then tested across real-world settings: bedrooms, offices, and nurseries. Engineers check for distortion, volume drop-offs, and any annoying tonal artifacts. Testers also listen for “loop points” in recorded tracks—bad loops create noticeable jumps in sound that break the illusion of continuity.

Sampling continues on the factory floor. During production, every few units are selected for audio checks using standardized decibel meters and spectrum analyzers. If deviations in sound profile or output volume are detected, the line is paused and recalibrated.

How Do Brands Customize Sound Signatures?

Many brands aim to differentiate their white noise products by designing custom sound signatures. This often involves working with acoustic engineers to develop exclusive sound profiles or recording unique